Our Services

First-class maintenance of your turbocharger may extend its operating life and prevent unforeseen damages and high repair costs.

Our experienced turbocharger engineers are available at any moment for performing overhauls and maintenance, on board (worldwide assistance) as well as in our own workshop.

01

Repair

Our facility is equipped with modern high-quality machinery and tools to ensure the best maintenance and repair for your turbocharger.

We offer a full range of possibilities to support our customers cost effectively:

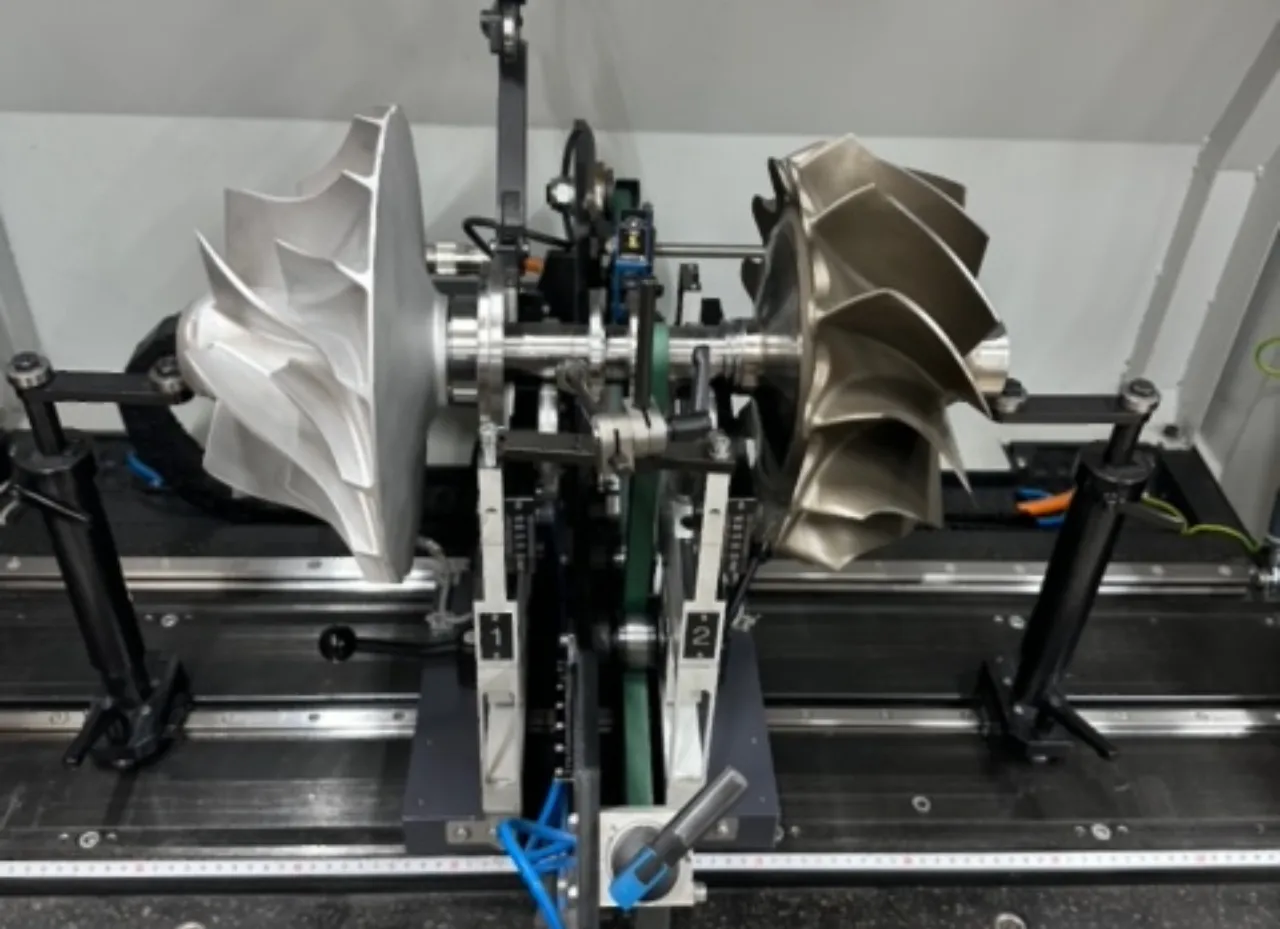

Dynamic balancing

- Our workshop is equipped with a state-of-the-art Schenck balancing machine, available for dynamic balancing of your rotor. Damaged rotor blades can cause imbalance on the rotor and once this imbalance exceeds the permitted tolerances, it will cause vibrations. These vibrations may damage the bearings and in worst care even the complete turbocharger which will result in high costs for replacement.

- Therefore, our service team will perform balancing checks with highest care and precision according to the makers’ standards. Any possible imbalances detected by the balancing machine will be corrected by grinding the unit within the permitted values. A clear balancing report will be added to the final inspection report.

Blasting and cleaning

- In order to identify the condition of the turbocharger, our workshop offers all machinery for blasting and cleaning of the parts. MBS has a ceramic blasting installation as well as an ultrasonic bath for steam cleaning purposes. For further identification of possible damages, parts such as the nozzle rings can be dye-checked to discover any presence of cracks.

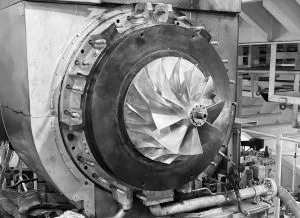

Rotor and turbine blade repair

- The combustion of any engine particles (mainly caused by poor fuel quality!) can result in damaged and bended blades of the turbocharger. Also foreign objects, passing through the nozzle ring, can cause a required repair which can be executed by our experienced service team in our workshop.

- Working and communicating closely together with the customer, we try to find the most economical and effective solution in order to avoid the cost of full replacement.

02

On board / workshop overhauls

-

- Once the turbocharger is in our workshop, it will be disassembled, cleaned and measured. Our clear inspection report will indicate if parts can be repaired or need to be replaced. Thanks to our large stock we have the possibility to offer any replacement parts immediately. With our in-house technical knowledge and experts we are able to give you any technical advice or support that you may require to enhance the performance of your turbocharger.

- If the customer accepts the quoted repair / replacement, we will make sure to perform the overhaul with highest precision and care without giving in on quality. Once the turbocharger is ready for dispatch, or is re-installed on board, we provide the customer with our final and detailed overhaul report for future purposes.

03

Cartridge exchange plan

In order to save time and money for the customer, MBS Turbo Holland BV also offers a worldwide cartridge exchange service. Old units brought to our workshop will be reconditioned in consultation with you.

Once the old unit is fully reconditioned and ready for installation, it can be stored in our warehouse in anticipation of any needed call-off on short notice. In a short amount of time, it can thus be exchanged on board with another unit, ready for repair in our workshop.

This is particularly interesting for ship owners having many same type turbochargers in their fleet.